Manufacturing facilities which include High capacity variable Speed Blenders for Powder & liquid products , Stainless Steel reactors, Driers, Milling machine, Pulverizers, Grinders, Filter press, Scrubber and Condensers.

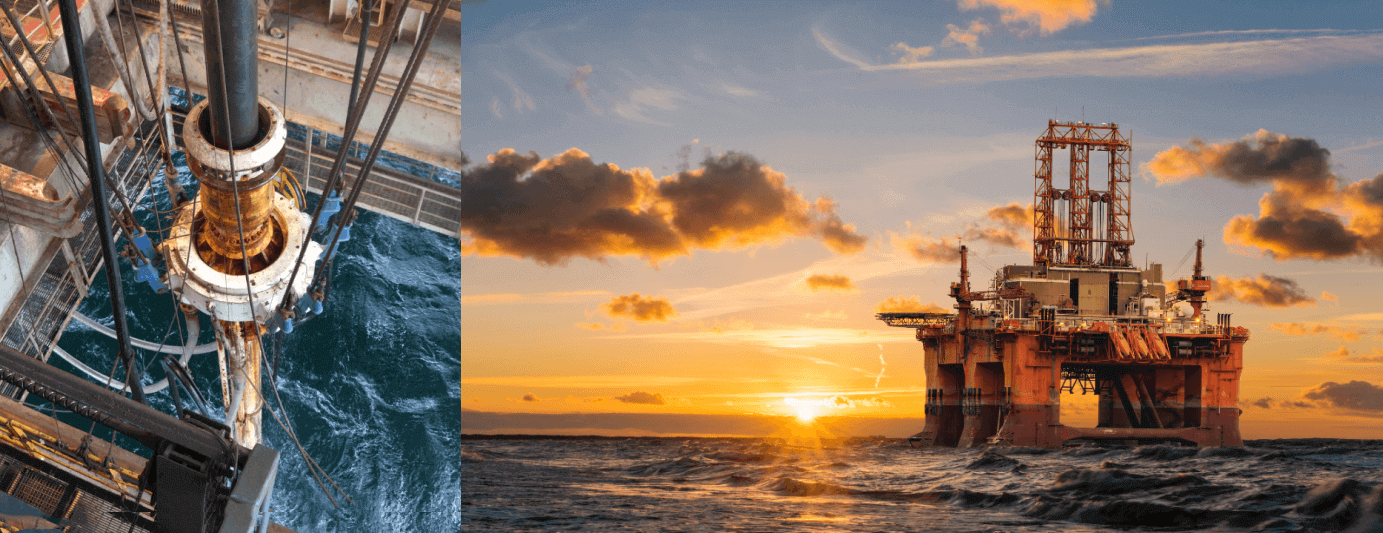

We are focused towards manufacturing & providing customized completion products and all types of drilling, production, stimulation, cementing and completion fluids for water base & Oil base mud.

Over the years we have built a strong foundation of trust in our relationships with our clients, who have come to trust our product and solutions based on their experience with us.

Our QA/QC department is equipped with latest and appropriate testing equipments which enables us to keep a close watch on the products used in manufacturing as well as manufactured.